The busiest time of year for China is coming up quick as Chinese New Year quickly approaches on calendars everywhere. Chinese New Year is celebrated across the nation so all businesses, including factories, will close throughout China. It is during this holiday that workers travel so that they can be with their families to celebrate the new year and all manufacturing shuts down.

Shippers in the United States that import or export goods to and from China will face a considerable logistical challenge during this time of year. Preparation and planning will help shippers to effectively manage any challenges that do arise as a result of Chinese New Year.

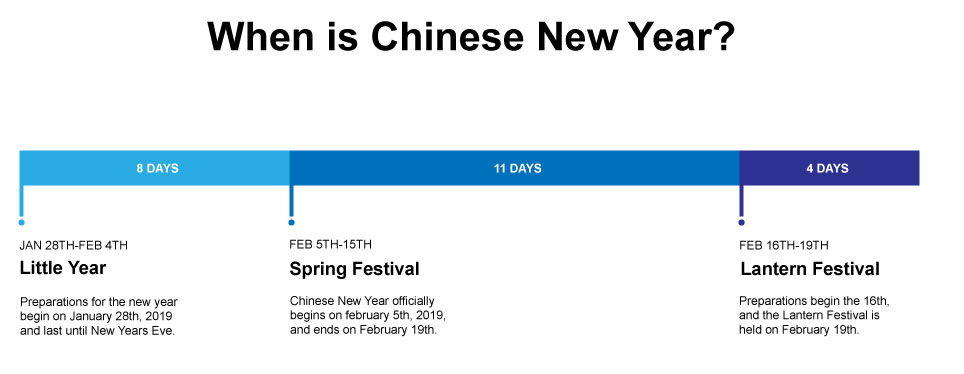

The chinese New Year timeline

Chinese New Year which is also known as the Lunar New Year, and is sometimes referred to as the Spring Festival, is officially a weeklong holiday that can last up to about 23 days. This holiday is also celebrated in countries that have significant Chinese populations, including Taiwan, Hong Kong, Indonesia, Cambodia, and Vietnam. The holiday is based on the lunar calendar and takes place at the end of February.

For the upcoming New Year, the entirety of the holiday falls within February, but many factories will stop their operations until the beginning of March. One or two weeks prior to the holiday factories will increase production. This results in a surge of freight. During the holiday itself, businesses close completely. Production resumes roughly two weeks after the holiday. The delay is the result of two celebrations that take place during this time. The first is the official holiday and the second being a traditional holiday.

The consequences of not preparing

Chinese New Year can be detrimental to shippers that are unaware of how this really impacts a supply chain. Again, even though the holiday itself only lasts for one week, many factories stop operations for at least two weeks so that their employees have enough time to travel across Asia to join their families and celebrate. Remember that the manufacturing industry within the area is heavily populated with Chinese citizens that strongly rely upon migrant labor and this holiday is a chance for that working population to return home wherever that may be.

For many people who work in factories along the coast, they may have to travel far inland to be with their families. In some situations, employees never return to their jobs following the holiday. In this case, companies are delayed trying to hire new labor while simultaneously trying to compensate for having taken so much time during the holiday.

Believe it or not, many employers don’t have concrete answers for when or how many of their employees will return after the holiday. In some cases, it might take two or three weeks following the holiday for timeliness and efficiency to return to normal operational standards. Many ocean freight carriers will cancel sailings because of the increased congestion which only exacerbates the existing problem of shipment delays and can prove problematic for shippers who have serious deadlines around this time of year.

The later your orders are submitted, the further back in the production queue your order will land. As companies face bottlenecks as a result of this holiday, one month’s worth of orders end up getting tackled later and the first orders that were received will be the first orders processed. In fact, many Chinese companies will process orders from preferred partners before handling any others.

Best practices for shippers

There are risk management steps that you can take to prepare for Chinese New Year. The first is to simply be aware of when it takes place. Remember that Chinese New Year can prevent your business from accessing manufactured goods for at least one month so having extra stock ahead of time can help you. Mark your calendar and plan your orders and deadlines around this time. Remember that Chinese New Year falls on a different day every year but it will typically take place between January and February. For the upcoming 2019 calendar year, it begins on February 5th. In the calendar year of 2020, it starts on January 25th. Just be cognizant of when this holiday begins if you’re doing business with countries participating.

It can also help you to forecast what your expected orders will look like, the information you can give to your carrier. It is in your best interest to inform your carrier about whatever shipments are a priority in case there is limited space. This will allow your carrier to prioritize what gets sent, and when.

Communicate with your supplier and your logistics provider ahead of time with the knowledge that manufacturers could shut down completely. Better yet, place your projected orders early to prepare. The earlier you place the orders the sooner they will be processed and shipped to you after the holiday. If possible, place your orders before the start of the new calendar year and avoid last minute orders in the month of January to prevent any delays.

What to do if your run into issues

Overall it is important to take the steps necessary to prepare your company against any delays. Being cognizant of the holiday and making sure that orders are shipped long beforehand can help you to avoid last-minute delays. If you do run into issues, communication is key. It is better to over-communicate with your customers and partners along the supply chain than to leave them in the dark. Delays are expected in the logistics industry and especially during this time of year. Shippers who plan ahead and take proactive steps to solve problems will be the ones with the least amount of stress and the most success this holiday season.